Accelerating Material and Product Development with AI-Powered and Virtual Experiment Platform

Simreka's flagship AI-powered cheminformatics and virtual experiment platform is a game-changer in the process of developing new materials and products by significantly enhancing efficiency, accuracy, and innovation.

- Faster Time-to-Market: Reduce ideation-to-launch timelines by up to 60–70% through AI-assisted experimentation.

- Lower Development Costs: Cut down expensive lab iterations and pilot runs through virtual prototyping.

- Higher InnovationThroughput: Explore 10x more viable candidates and substitutes using intelligent search and filtering.

- Built-in Regulatory & Sustainability Compliance: Simulate against REACH, GHS, and eco-labels upfront — saving time later.

- IP & Knowledge Retention: Keep data on-premise or securely train ChemAssist on proprietary know-how — your R&D stays yours.

Forward Simulation

Start with Materials,

Predict the Outcome

Forward Simulation in Simreka’s Virtual Experiment Platform allows R&D teams to input specific chemical formulations or material combinations and simulate their expected properties, behavior, and performance under defined process conditions.

-

Predict Performance Before Prototyping: Model how a formulation or material will behave without expensive and time-consuming lab trials.

-

Accelerate Development Cycles: Reduce the number of physical iterations needed to reach optimal formulation.

-

Achieve long-term goals Minimize Waste: Avoid overuse of rare, hazardous, or costly materials through data-driven predictions.

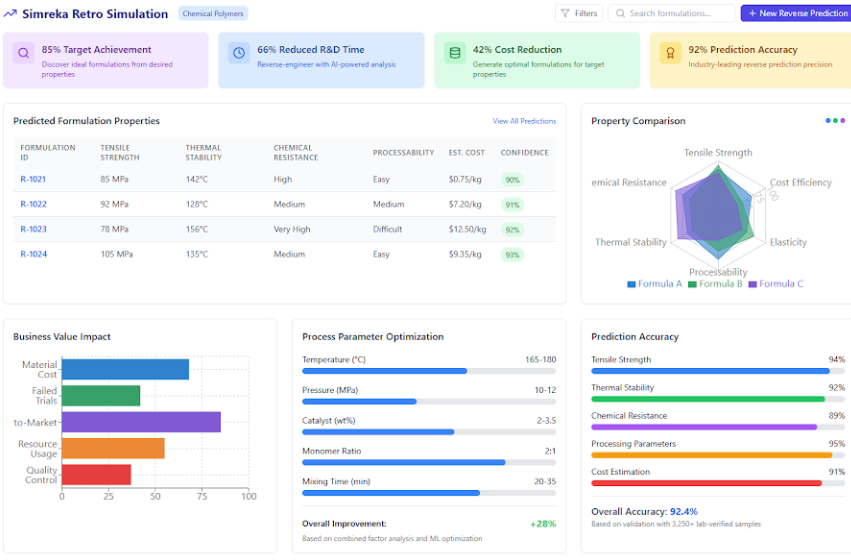

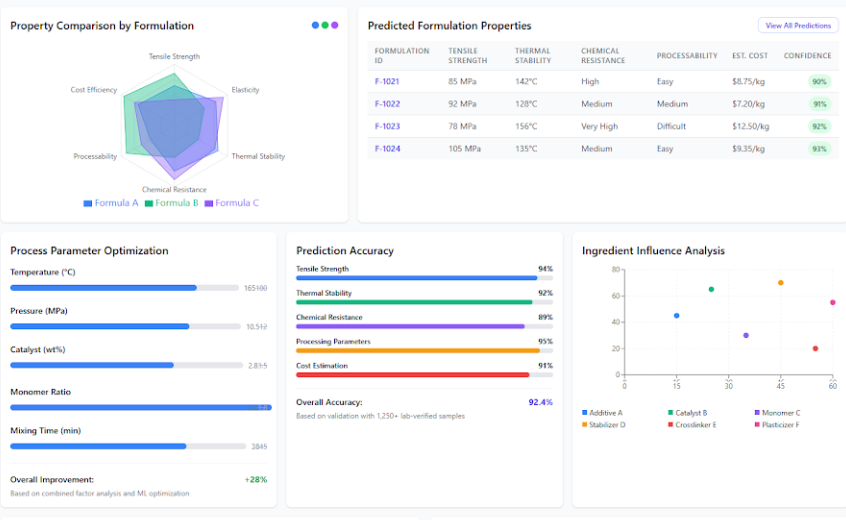

Retro Simulation

Design Backwards from Product Goals

Retro Simulation module flips the conventional workflow: you input your target product specifications, and the AI suggests materials, formulations, and process conditions most likely to meet those goals. This radically shortens the path from product idea to testable prototype.

-

Goal-Driven Innovation: Define desired output first (e.g. biodegradable, specific hardness, cost cap) and let the system propose how to get there.

-

Faster Go-to-Market: Eliminate upfront guesswork and iterations by starting with your end goal.

-

Uncover Non-Obvious Solutions: Tap into Simreka’s knowledge base and AI engine to find alternative formulations or materials outside of human bias.

-

Better Compliance & Sustainability: Build formulations that already meet regulations or green targets.

Whatever industry you’re in, we’re here to help you thrive

Simreka’s AI-driven software empowers companies to rapidly discover and design chemical formulations and materials that precisely align with predefined technical or performance specifications.

By leveraging advanced simulation models and proprietary datasets, our platform significantly reduces the trial-and-error cycle inherent in traditional R&D processes.

Whether you're developing sustainable coatings, next-generation polymers, or cosmetic formulations, Simreka enables your team to:

-

Identify high-potential formulations in minutes

-

Explore alternative materials aligned with regulatory and sustainability goals

-

Reduce time-to-market and R&D costs significantly

-

Transform your formulation workflows with AI—from concept to commercialization.

-

Focus resources on the most promising materials and processes, guided by AI predictions and virtual experiment results.

Industry Use Cases

Use Cases for Virtual Experiment in the Chemicals & Materials Industry

Both Forward and Retro Simulation are core engines of Simreka’s Virtual Experiment Platform, giving you a bidirectional R&D superpower: the ability to predict outcomes from inputs and to engineer inputs from desired outcomes.

1. Sustainable Coatings

Achieve specific gloss, adhesion, water resistance, and low VOC levels. Rapid reformulation for eco-certifications, meet regulations, improve durability Reduced R&D cycles, faster compliance certifications, improved shelf performance

2. Polymers: Lightweight Auto Plastics

Replace petroleum-based polymers with biodegradable or recycled alternatives. Sustainable material substitution without loss in mechanical properties Lower material costs, new market positioning (eco-friendly), reduce waste

3. Cosmetics: Skin-care Emulsions

Formulate non-toxic, long-lasting creams with SPF and fast absorption. Faster time-to-market with consumer-safe and compliant products Reduction in clinical testing costs, increased speed of innovation cycles

4. Specialty Chemicals: Surfactants for Home Care

Tailor surfactants with optimal foaming, solubility, and biodegradability. Improve formulation efficiency, reduce dependency on high-cost proprietary surfactants Lower raw material costs, less testing redundancy

5. Regulatory Reformulation: Phthalate/PFAS Replacement

Replace legacy ingredients while keeping performance intact. Ensure global compliance without losing market share Avoid product recalls, reduced legal/regulatory risks

6. Detergents: Bio-based Laundry

Liquids Create formulations with stain removal efficacy and skin sensitivity. Better consumer safety, eco-label qualification, cost-effective enzyme usage Save formulation costs by reducing over-design, competitive eco-branding

7. Lubricants: High-temp Industrial Lubes

Formulate fluids with long life, thermal stability, and low volatility. Optimize for performance and service interval extension Lower downtime for end users, longer product lifespan

8. Paints & Inks: UV-curable Inks

Develop fast-drying, high-opacity inks for packaging and labeling. Speedy prototyping and color fidelity improvement Streamlined design-to-print pipeline

Both Forward and Retro Simulation are core engines of Simreka’s Virtual Experiment Platform, giving you a bidirectional R&D superpower: the ability to predict outcomes from inputs and to engineer inputs from desired outcomes.